Rising prices and security concerns raise important questions about America's energy options. Currently, the United States imports 66 percent of its oil – about 4.7 billion barrels per year or 9,000 barrels every minute. However, there are vast amounts of oil shale – a type of rock rich in kerogen, an organic sedimentary material – which can be converted into high-quality liquid fuels.

The U.S. Department of Energy (D.O.E.) conservatively estimates oil shale formations in Colorado, Utah and Wyoming contain 800 billion barrels of recoverable oil, more than three times the proven reserves of Saudi Arabia.

The D.O.E. projects continued rising oil prices in the coming decades. But as prices rise for other fossil fuels, technological advancements for shale oil extraction will make this U.S.-based energy resource more economically competitive. Most of the oil shale is located on federal land. Leases for 77 parcels of land were sold at auction to energy firms, but the Obama administration has cancelled those leases. If the administration eventually allows development, activist groups can use administrative and court challenges to delay production indefinitely. These obstacles must be removed in order to realize oil shale's full potential.

Efficiency of Oil Shale Production. Traditionally, oil shale rock was mined and shipped to a plant where it was superheated and collected when it seeped from the rock. Shell Oil's In-situ Conversion Process (ICP) heats the shale in the ground and collects the oil and gas released. The oil can then be sent directly to refineries. Shell has been testing this process in the Piceance Basin of Colorado. Shell says the ICP process can be profitable at oil prices as low as $25 a barrel.

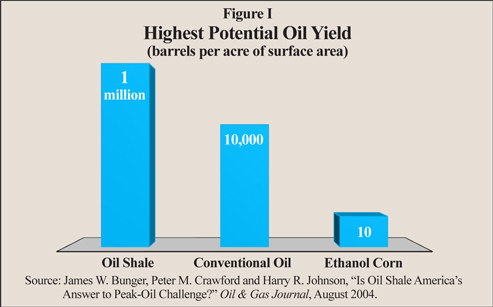

Per acre, oil shale is significantly more concentrated than oil and gas on Alaska's North Slope, Alberta's tar sands or ethanol production [see Figure I]:

- Some shale contains more than 1 million barrels of oil per acre (bbl/acre).

- Conventional oil yields about 10,000 bbl/acre.

- Corn yields 10 bbl/acre ethanol.

Oil from shale is ideal for use as premium jet or diesel fuel because of its high hydrogen content. Its combustion produces less carbon dioxide per unit of energy than conventional gasoline, according to the D.O.E.

National Security Benefits. U.S. dependence on energy imports increases its strategic vulnerability. The RAND Corporation estimates that Americans sent the Persian Gulf oil states more than $330 billion in 2005. Diversifying energy production and reducing dependence on imported oil in favor of more secure domestic sources would enhance national security.

Economic Benefits. Domestic oil shale production would provide substantial economic benefits, according to RAND:

- A 3 million bbl/day industry could generate $20 billion in annual profits while reducing prices for consumers.

- As many as 100,000 new jobs could be created by a 2 million bbl/day shale oil industry.

- The D.O.E. estimates that, in addition to tax revenues, federal and state governments would receive royalties and lease payments topping $2 billion a year.

Efficiency. Oil shale production requires more energy than conventional petroleum. However, the D.O.E. reports that it is significantly more efficient than ethanol, and at least as efficient as oil from tar sands. Measuring efficiency by the energy required to produce equivalent output:

- Conventional oil production is 92 percent efficient.

- Depending upon the production method used, oil shale efficiency ranges from 78 percent to 89 percent.

- The efficiency of tar sands ranges from 82 percent to 86 percent.

- At 52 percent, ethanol has the lowest efficiency of comparable motor fuels.

Oil shale is richer in energy content and more concentrated than tar sands, and as the industry matures, production should become more efficient, as it has with Alberta's tar sands.

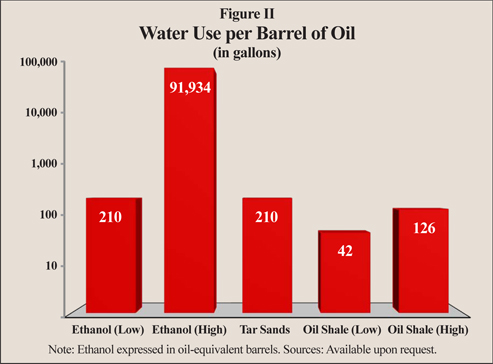

Water Use. Oil shale production requires significant amounts of water, but the D.O.E. estimates there is enough available. In fact, oil shale uses less water than ethanol and tar sands. As Figure II shows:

- Crops for ethanol require from 210 to 91,934 gallons of water per oil-equivalent barrel, and they are increasingly grown in areas requiring intensive irrigation.

- Each barrel of oil from tar sands requires about 210 gallons of water.

- A barrel from oil shale requires 42 to 126 gallons of water.

Thus even the most intensive water use for oil shale production requires 40 percent less than tar sands or the most efficient ethanol production. The least intensive water use for oil shale requires 80 percent less than tar sands and just 0.043 percent of the most water-intensive ethanol use.

Removing Barriers to Oil Shale Production. The D.O.E., the Task Force on Strategic Unconventional Fuels and other energy experts say the nation's untapped oil shale offers a long-term source of reliable, affordable and secure energy. Public lands should be leased and the permitting process for production facilities should be streamlined. For instance, firm deadlines could be set for filing administrative or court challenges. The scope of such challenges could be narrowed. The right to challenge leases in court could be limited to those who claim direct harm.

H. Sterling Burnett is a senior fellow and Tomas Castella is a research assistant with the National Center for Policy Analysis.